Home / Materials & Solutions / Industrial Market / Foundry Solutions

Foundry Solutions

Quartz sands and resin sands solutions

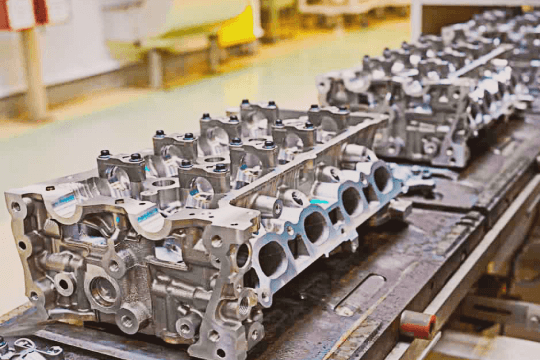

Casting is a productive process used in the manufacturing of automobile engine blocks,

agricultural parts, pipe fittings, mining parts, railway parts, wind power parts, that is, any type of casting.

For this market, Jundu offers solutions in Quartz Sands (base sand) and Resinated Sands

(Shell Molding process). The differential elements in its specification are grain purity, low

levels of fines, high sphericity and roundness of the grains, and pH close to neutral.

Highlights

This set of attributes provides stability and advantages in the manufacturing process of the molds and cores used in the casting of the parts:

- Increased outflow of gases, during the casting of the parts.

- Better mechanical recovery of molds and cores.

- Less mold expansion at high temperatures.

- Versatility during the manufacturing of molds and cores.

- Reduction of casting costs.

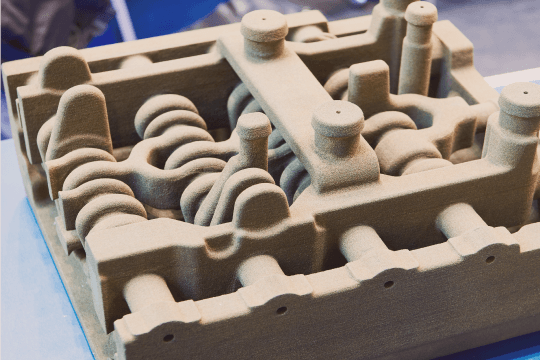

3D Printer Solutions for Molds

Precision and detail to the molds

The world has changed and the way we do things is also changing!

Attentive to the trends and concerned with Sustainability, we bet on the development of 3D Printer Solutions, more precision to the molds and correct balance of resources.

Talk to our experts

Jundu has a team of Application Engineering experts ready to understand your challenge!